vickers hardness test asm|vickers hardness test procedure : solution Static indentation tests: A ball, cone, or pyramid is forced into the sur-face of the . webThe easiest and most efficient development tool for use with the MAQ®20 Modular Data Acquisition and Control System. The main screen of this out-of-the-box software shows a representation of the system including the communication module and all installed I/O modules. This graphic is updated as I/O modules are added to or removed from the system.

{plog:ftitle_list}

web22 de dez. de 2020 · Mombo goes by many names: ‘Mother of All Camps .‘Place of Plenty’.‘The Land of Milk and Honey’, and more. Super-luxurious, offering some of the best game viewing in Africa, it is Wilderness Safaris ’ flagship camp – the ultimate accommodation in Botswana’s Okavango Delta, one of the most paradisical spots on Earth.

This article describes the principal methods for macroindentation hardness testing by the Brinell, Vickers, and Rockwell methods. For each method, the test types and indenters, scale limitations, testing machines, calibration, indenter selection and geometry, load selection and impression .Provides an overview of the hardness testing of metals, plastics, rubber, and .This chapter covers some of the most widely used hardness testing methods, .Static indentation tests: A ball, cone, or pyramid is forced into the sur-face of the .

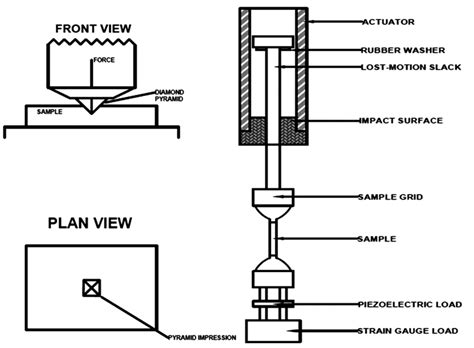

vickers hardness testing machine diagram

vickers hardness test procedure pdf

iv Instrumented Indentation Testing ...86 New Insights Via Nanotesting ...87 .Most of the hardness tests used in industry, including Rockwell, Vickers, Brinell, and .

The revised and updated second edition features expanded information on .

Provides an overview of the hardness testing of metals, plastics, rubber, and other materials based on current standards and practices. Covers technical developments such as the introduction of image processing in the .

This chapter covers some of the most widely used hardness testing methods, including Vickers, Rockwell, and Brinell tests, Shore scleroscope and Equotip hardness tests, and .Static indentation tests: A ball, cone, or pyramid is forced into the sur-face of the metal being tested. The relationship of load to the area or depth of indentation is the measure of hardness, .

Most of the hardness tests used in industry, including Rockwell, Vickers, Brinell, and Knoop methods, are based on static measurements that have become standardized over the years. The practices and procedures associated with .

1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10 -3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness . The revised and updated second edition features expanded information on microhardness testing, specialized hardness tests, and hardness testing standards. .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .

vickers hardness test procedure

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11E01 ASTM|E0384-11E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials > new BOS Vol. 03.01 Committee E04 $ 129.00 In stock

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force units are kilogram .

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-10E02 ASTM|E0384-10E02|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials> new BOS Vol. 03.01 Committee E04 $ 129.00 In stock 1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces from 9.807 × 10-3 N to 19.613 N (1 gf to 2 kgf).. 1.5 Additional information on the procedures and guidance when testing in the microindentation force range (forces = 1 kgf) .Designation: E 140 – 07 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11 ASTM|E0384-11|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials> new BOS Vol. 03.01 Committee E04 $ 129.00 In stock

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force . 5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the four .At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). 1.Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a .

higher. At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). N. ote The revision incorporates ASTM E92, Test Method for Vickers Hardness of Metallic Materials, into ASTM E384. ASTM E92 is under the jurisdiction of ASTM International Committee E28 on Mechanical Testing. According to Edward Tobolski, chairman of both Committee E28 and Subcommittee E04.05, in the past, hardness testers normally were .15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces from 9.807 × 10-3 N to 19.613 N (1 gf to 2 kgf).

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. Standard Test Method for Knoop and Vickers Hardness of Materials E0384-10E01 ASTM|E0384-10E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials> new BOS Vol. 03.01 Committee E04 $ 117.00 In stock

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests.Knoop, Rockwell, and Vickers hardness tests. . example, both the hardness test and the tensile test measure the resistance of 2 / Hardness Testing Hardness Testing, 2nd Edition, 06671G . Tobolski, Introduction, Mechanical Testing, Vol 8, .

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

Indentation Hardness Testing. E140-12B(2019)e1 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness . E92-82(2003)e2 Standard Test Method for Vickers Hardness of Metallic Materials (Withdrawn 2010) 1.1 This test method covers the determination of the Vickers indentation hardness of advanced ceramics. 1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use.It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

WEBEuropean Roulette is a classic gambling game that has been a favourite all around the world ever since its creation. Roulette is a very simple and straight forward game where the game aims to correctly guess wherein the wheel the white ball will land. One can play European Roulette online for money or they can also play European Roulette for fun.

vickers hardness test asm|vickers hardness test procedure